Concrete Polishing in Phoenix AZ

Concrete polishing is a multi-step procedure by which a finished concrete slab is initially ground, polished and sealed using bonded in abrasive materials so as to sculpt a concrete surface. It is then polished with each successive cut to attain a specified level of finish. After the concrete polishing operation, a clean and clear surface is achieved whereby further modifications can be introduced if required. A concrete polishing process produces highly consistent and smooth finishes and hence is highly demanded by various industrial sectors such as automotive, marine, decorative, residential and commercial in Phoenix, AZ.

The concrete polishing procedure starts with grinding of the underlying rock face that is done by a diamond wheel. The roughness of the diamond wheel enables the grinding of the concrete surface to take place at a rate equal to or slightly higher than the rate of drying of the concrete. Once this is done the next step is to apply a coating of polyurethane onto the diamond wheels after which a grinding operation can take place. Once this has been done the floor can be sealed with an electrostatically charged sealer. These floors normally last for more than two decades and even the most hard-wearing ones are seldom exposed to wear and tear because of this fact.

Unlike other similar operations, concrete polishing is highly effective and does not require high-level of maintenance. In fact, it only requires cleaning once in every three or four years thereby minimizing the expenses incurred on other types of maintenance. Unlike other methods such as honing and sealing that require high-quality products and frequent monitoring, this is an easy multi-step process that can be carried out by inexperienced users without any worries. Hence, it is highly recommended by the majority of industry experts to their clients so as to ensure maximum longevity of their concrete polishing.

Contact Us

What You Need To Know About Concrete Polishing Services

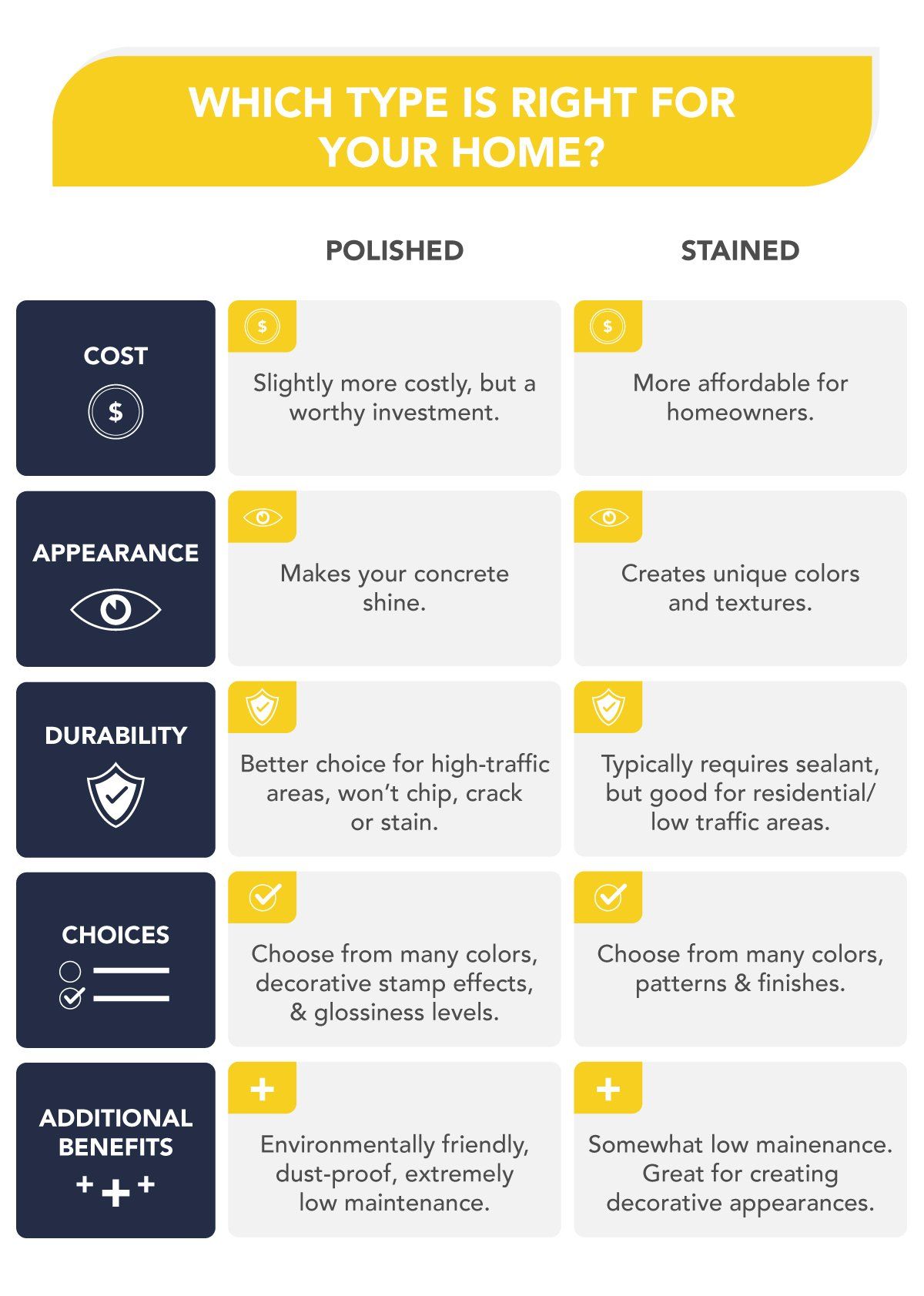

If you are considering concrete polishing for your home or office, you should know more about the process and the cost involved. We've outlined the grades of polished concrete and the various methods used to achieve that look. To learn more, read on to discover the benefits of this process and the many benefits you can enjoy. The final product is beautiful and durable and requires little maintenance in Phoenix, AZ. You'll be thrilled with the results and so will your friends and neighbors.

Methods Of Topically Polished Concrete

There are many methods to achieve a glossy concrete surface. A topical polish is one option. This process uses a topical sealer to fill in gaps left by the grinding process and harden them to produce a smooth concrete surface. However, this method is less refined than mechanical polishing, leaving the floor with a rougher finish than the maximum refinement. Topical polishing may be a less expensive option, depending on the desired sheen.

Reactive and nonreactive concrete surface colors are available for a glossy finish in Phoenix, AZ. Reactive materials penetrate the concrete to produce a permanent color. Nonreactive dyes are subject to change due to environmental conditions, whereas reactive materials are permanent. However, there are several advantages of reactive surfaces. Here are some of the benefits of using reactive colors. They are more durable than nonreactive dyes, leaving no visible surface film.

The main advantage of using topically polished concrete is that it can be put into service almost immediately. In addition, this method can be installed while the facility is in full production. Our concrete polishing service in Phoenix, AZ offers excellent light reflectivity, which gives the area an overall clean and bright appearance. The process involves multiple steps, each consisting of finer grit abrasives. Each step is refined to the microscopic level.

Combined polishing methods are another option to consider. Mechanical polishing is more expensive than topically polished concrete, but it is easier to maintain and lasts longer. The difference between topically polished concrete and sealed concrete is in the amount of work required to achieve the desired sheen. The mechanical method requires less honing and grinding, while the sealed process does not. It may be more expensive, however, if you need a large area.

Grades Of Polished Concrete

There are various types of grades of polished concrete and each has its benefits and drawbacks. Some grades are easier to maintain than others and can be applied to areas that are subject to high traffic. Compared to other floor coverings, polished concrete is less expensive to install and requires less maintenance. Furthermore, it is highly resistant to damage and bacteria. Unlike wood and carpet, polished concrete does not retain heat, making it a popular choice for places with heavy traffic.

There are three grades of polished concrete: coarse, medium, and fine. Each grade has a different level of shine. Some grades are shinier than others, and some are slightly dull. While it may be hard to tell which one is the best option for your property, you can always check the finished surface on site while it is still wet. Once you've chosen the grade of polished concrete, the next step is to inspect the slab for damage or unevenness.

Phoenix Concrete Polishing Contractor is a nonprofit organization dedicated to the development of standards and guidelines for the concrete polishing industry in Phoenix, AZ. With a high-quality product, you can rest assured you are getting the best value for your money. Our company also offers training and educational opportunities for concrete polishing professionals. Our company is also dedicated to making sure that concrete professionals are using the same terminology and standards when designing a floor. We will help ensure you get the perfect finish for your project.

Although concrete epoxy floor is extremely durable and resistant to wear, it does not require any sealant. It may stain easily and show watermarks. However, sealing polished concrete helps protect it against these and also makes cleaning easier. There are also several types of sealants available, including UV-resistant sealants that change color under ultraviolet light. If properly maintained, polished concrete floors can last for years. They can be refreshed every years. They are also not slippery. Unlike other types of hard flat flooring, polished concrete does not become slippery when wet.

Cost Of Polished Concrete

The cost of polished concrete depends on its type and the number of steps that are required. Large commercial and industrial floors are more expensive than small residential floors in Phoenix, AZ. However, some companies waive delivery fees in exchange for higher repair and installation costs. In any case, the cost of polished concrete depends on the quality of the subfloor. It's important to choose the correct subflooring to ensure a flawless finish.

Depending on the size of the concrete floor restoration and the complexity of the design, polished concrete flooring can cost anywhere per square foot. However, you should be aware that you're not going to be able to know the exact price before the job begins. It will cost more if you want elaborate designs, such as multiple colors, custom patterns, and scoring. And, because the process involves a lot of time, you need to pay more for a high-gloss finish.

There are two main types of polished concrete: grind and seal and mechanically polished. Although "grind and seal" concrete is the least expensive option, it's more durable than other options. The most expensive option is mechanically polished concrete, which will cost you a lot more than either grind and seal or honed concrete. Despite its high cost, mechanically polished concrete is a much more beautiful and durable option than either of the two alternatives.

How Our Concrete Polishing Services Can Enhance The Appearance Of Your Floor

Regardless of your preference, our concrete polishing services in Phoenix, AZ can enhance the appearance of your floor. Whether you prefer a dry polish or wet polish, you can find the right method for your floor in this article. Learn about ADA compliance, environmental benefits, and cost effectiveness. You'll be pleasantly surprised by the results. Whether you need to repair a cracked floor or add luster to your concrete, we've got you covered.

Wet Vs. Dry

Wet vs. dry concrete polishing services differ largely in the amount of labor and materials used. Both processes can result in beautiful surfaces, but wet polishing is a more expensive option. In addition, the machines and machinery used in wet polishing can be very hot. The water helps cool the machinery and floors, which is an important factor. In contrast, dry polishing services don't use water, so the heat from the grinding process remains on the floor.

Concrete polishing services use a high-powered machine that uses discs similar to sandpaper to wear down the concrete. These discs begin with coarse segments of diamond bonded together in a metallic matrix. During the process, they remove stains, blemishes, coatings, and pits. Some polishing companies require more than one session to achieve the desired result, as it may require multiple visits.

In wet concrete polishing, the diamond tooling is cooled by water, reducing the friction between the diamond and the surface. This method is more effective when there are no movable objects nearby, because it produces less dust, but requires more cleanup and containment. Because of the water-based abrasive, dry concrete polishing services must be done in an environment with adequate ventilation.

Environmentally Friendly

For many reasons, environmentally friendly concrete polishing services are preferable to traditional flooring solutions. They are less abrasive than acid washing and have a minimal impact on the environment. In addition to its durability, polished concrete offers a number of environmental benefits, including a low VOC content. Unlike carpet, laminate, or VCT Tile, polished concrete does not have to be replaced, thereby reducing the impact of concrete polishing on landfills.

When compared to traditional flooring options, polished concrete is more eco-friendly. It reduces energy costs and other costs associated with flooring. Improved lighting reduces energy bills and increases productivity. Additionally, polished concrete floors are safer, reducing tire wear and making floors more suitable for heavy traffic. Environmentally friendly concrete polishing services may be the perfect solution for your home or business. Choose your environmentally-friendly concrete polishing services wisely.

Concrete polishing services also improve the look of your property. It can transform grey concrete floors into stunningly bright, clean, and polished surfaces. Not only are these floors easy to clean with a wet mop, but they also contribute to a more pleasant environment. Furthermore, because polished concrete is breathable, dust will not accumulate on them. In addition, these floors do not support growth or mold. Environmentally friendly concrete polishing services are highly recommended in Phoenix, AZ, as they can be used on stairs and even in underground garages.

Advantages And Disadvantages Of Concrete Polishing Services

If you are looking for a durable, mirror-like finish for your home or business, you should consider our concrete polishing service in Phoenix, AZ. Concrete polishing is the process of finely sanding concrete to achieve a finish that is like a mirror. A sealer is also applied during the polishing process, which helps to lock in the concrete density and provides sheen and durability. This sealer also helps to maintain the shine of the polish from the inside out.

High Gloss Polishing

The high gloss concrete polishing process produces floors with a beautiful shine. The finished floor can have a specific Distinctness-of-Image (DOI) Gloss or Image Clarity Value ranging from 0 to 100. The process uses heavy duty polishing machines with diamond-impregnated disks. Although high gloss concrete polishing is not a do-it-yourself project, it's easy to maintain and can be dyed to match your style. Additionally, concrete flooring is easy to clean and is available in a variety of patterns.

The glossy effect of high gloss concrete is modern, elegant, and long-lasting. Phoenix Concrete Polishing Contractor specializes in high-gloss concrete floors in Phoenix, AZ. With this innovative process, you can get a high gloss floor that meets your budgetary requirements. The highly polished concrete lends itself to a contemporary, clean aesthetic. You can also customize the look of your floor to achieve the look you want. Because polished concrete is more durable than plain concrete, it can last for years.

The benefits of high-gloss concrete are many. For one, it eliminates surface roughness and creates a dust-free surface that's 100% dust-free. Additionally, polished concrete increases ambient lighting, which can help reduce your facility's energy costs. The polished concrete floors also project a clean, bright image, which is one of the main reasons why many companies choose this material. Unlike other floor coatings, high-gloss concrete is extremely durable and requires very little maintenance.

Dry Polishing

The benefits of dry concrete polishing are obvious. The slurry is much less hazardous to the environment than its wet counterpart. Furthermore, there is less chance of exposing workers to dangerous dust. It also saves on time as no slurry is left behind. The downside to dry concrete polishing is that it produces a relatively low luster finish. This process has been around for years but has certain disadvantages. We'll look at them below.

Wet and dry concrete polishing both have pros and cons. Wet polishing is faster and less expensive, but can leave gouge marks in your floors. Dry polishing is also cleaner and faster, and can be vacuumed up afterward. Wet polishing can also leave debonding residue. So, which one is better for you? Consider your preferences. Once you've decided which method is best for your project, read on to learn more about each one.

You'll need a team to complete this work. A concrete floor restoration project is a complex undertaking that requires specific knowledge and skill in Phoenix, AZ. As such, each trade will be responsible for a specific part of the project. In addition to a solid knowledge base, there are various ways to protect the concrete from damage and stains. You'll need to make sure that each of the people working on the project understand their responsibilities. Having a pre-slab meeting with your team will help to hold everyone responsible and improve the final appearance of the polished concrete floor.

Epoxy Coatings

A mechanical polished concrete is a common surface type, and it is often used in retail spaces, showrooms, and warehouses. It is also popular in residential settings, including garages. Unlike an epoxy coating, polished concrete wears off over time, leaving behind a visible aggregate layer. However, the durability of epoxy coatings is far greater, so if you're looking to protect a concrete floor for years to come, you should consider an epoxy coating.

Although some types of epoxy products are eco-friendly, not all are. Some contain chemicals that are harmful to the environment. Make sure to ask the contractor if they use green epoxies when discussing flooring options. If you're considering epoxy for concrete polishing, be sure to learn about the process and what you should expect. Epoxy coatings are very versatile and can be used in a variety of locations, including garages, commercial kitchens, and other places that are prone to chemicals.

An epoxy coating can provide additional protection for a concrete surface, making it more durable and resistant to chemicals and heavy traffic. It also provides a unique shine, which will impress house guests and clients alike. It can also protect concrete floors for years, allowing them to take significant abuse. Because there are no seams or cracks, an epoxy coating can be easily cleaned, and will not stain or dull the surface.